General Information

The truck is built on a Freightliner commercial chassis, with a diesel engine and a separate diesel generator. It weighs more than 17,000 pounds (16,740 lbs empty). It is 12 feet high, and 10 feet wide at the mirrors. It has an automatic transmission. As with any heavy duty vehicle, it does not stop, corner, or accelerate like a car. Allow extra space and time to stop or perform any kind of maneuver, do not tailgate. Use the side mirrors to observe what is going on beside you and behind you. Be aware that you may have a blind spot in the mirrors for vehicles next to the truck. Unlike many large vehicles, the front wheels can turn very sharply, making the vehicle more maneuverable, but also increasing the opportunity for the rear of the truck to swing in the opposite direction and hit something. When you turn sharply left, the rear of the truck goes right, and vice versa.Transmission and Mountain Driving

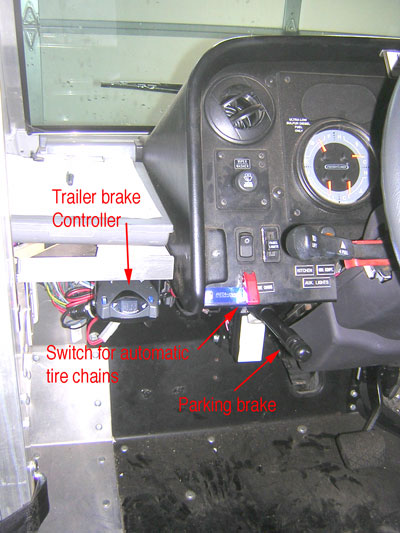

The transmission is similar to an automobile automatic transmission, except that it has no "Park" position. R is reverse, N is Neutral, D is drive. 3, 2 and 1 keep the transmission in a lower gear for going down steep hills, such as are found in the mountains. If the vehicle is accelerating downhill, or if you see a sign warning of a steep downgrade, slow down and downshift. It is always better and safer to start down a steep hill in a lower gear and then shift up later, than to start in a higher gear and have to use the brakes hard and downshift. On steep mountain roads, the truck may accelerate down the hill even in 1st gear. The engine braking is somewhat limited; If you have to use the brakes quite a bit, pull over and stop every few minutes to check the brakes and to let them cool down.The

transmission in this vehicle does not have a "Park"

position! It

is mandatory to apply the parking brake before you

turn off the engine

or get out of the vehicle. Be sure to chock the

wheels. If parked on a steep grade, turn the

steering wheel to reduce the risk of runaway.

When parking the unit, stop the

unit,

and then apply the parking brake by pulling up the black

handle

left of the steering wheel.

Starting the truck engine

Turn the ignition key to "On", wait for

most of

the

lights

on the dash above the key to go out, and then turn the

key to

"start". You might have to wait a little on cold

weather to heat

the glow

plugs.

After starting the engine, you should have oil pressure

in 15

seconds;

if not, shut down the engine and report the problem

Center of Dashboard

Note the sign that reminds you to apply the parking brake.

The oil and temperature gauges should read near the middle of the range, not too high or too low.